Nội dung bài viết

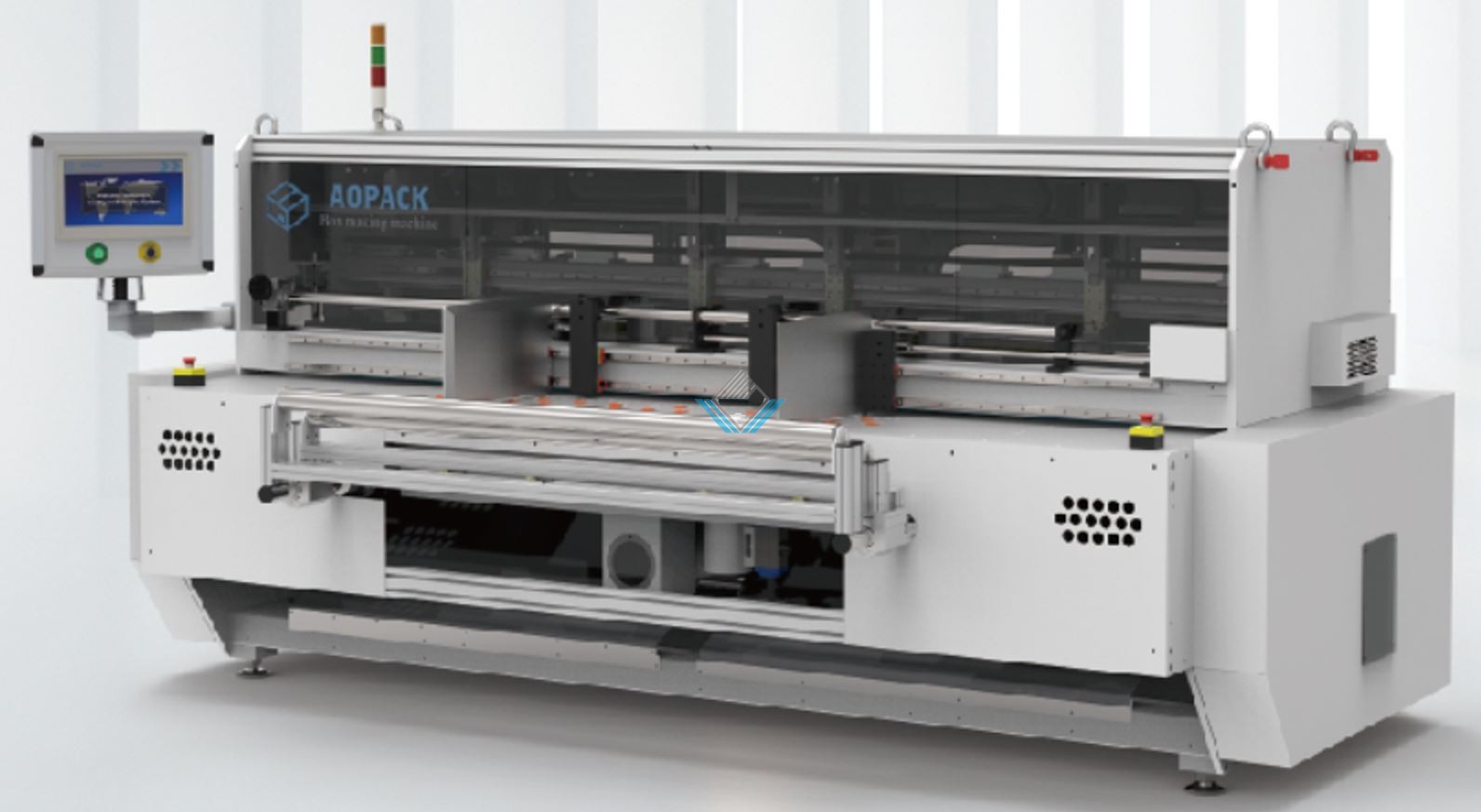

ToggleMÁY BẾ TỰ ĐỘNG MK 106CB (Cutting Blanking)

Technical parameters

| Parameter | Specification |

| Max. sheet size | 1060mm × 720mm |

| Min. sheet size | 350mm × 300mm |

| Max. die-cutting area | 1060mm × 705mm |

| Gripper margin | 810mm × 600mm (for outer packaging boxes) |

| Chase size | 9–17mm |

| Max. sheet dimension | 1096mm × 770mm |

| Paper range | 90–2000g/m² (cardboard) 0.1–2mm (cardboard) < 4mm (corrugated board) ≤ 2mm (corrugated, flatness ≤ 20mm/m²) |

| Die-cutting precision | ≤ ±0.075mm |

| Max. pressure | 2.6MN |

| Max. speed | 8000 sheets/hour |

| Max. feeding pile height | 1500mm (including pallet) |

| Max. delivery pile height | 1400mm (delivery) / 1100mm (finished products), including pallets |

| Machine dimensions | 7400mm (L) × 6000mm (W, including platform) × 2660mm (H) |

| Machine weight | Approx. 20,000kg |

| Power | Rated power: 13kW / Full load: 25kW |

| Air supply | Pressure: 0.6–0.7MPa / Flow rate ≥ 0.8m³/min |

| *Note: Speed and precision may vary depending on product type. | |

Standard configuration and functions:

Non-stop High-Speed Feeder Unit

- Non-stop high-speed feeder section

- Scaly-type feeder, maximum speed over 133 sheets/min

- Sheet deceleration function before front lay

- Adjustable suction nozzle

- Three anti-collision devices for the feeder head

- Motorized lateral adjustment of the feed pile

- Motorized lateral air blast and side lay device

- Push-pull side lay

- Pneumatic lifting feed frame

- Ultrasonic and mechanical double sheet detectors

- High-quality feeding belts

- Optical detection for side and front lays

- Forced gripper opening and sheet holding when sheet is missing

- Single-point electromagnetic clutch for feeder and main drive separation for easier operation

- Non-stop pile change with main and auxiliary feed piles

- Powerful suction feeder head with 4 pick-up and 4 feed suckers, adjustable suction angle

- Feeder heads and air valves with ultra-hard alloy treatment

- 4 sets of soft and hard brush wheels

- 10 sets of pressing wheels

- 4 sets of pressing balls

- 1 set of sheet inserter rods

- External pre-piling rack

- Comes with Becker vacuum pump

- 2 feed pile trays

Die-Cutting Unit

- Motorized pressure regulation mechanism

- Full set of imported worm and gear

- Adjustable chase plate combination with 3+1.2mm steel plate

- One 1.2mm die-cutting base plate

- Chase turning mechanism

- Lubricating oil cooling and lubrication system for main gearbox

- Independent lubrication system for gripper chain and transmission chain

- Torque limiter overload protection device

- Full set of imported anodized aluminum gripper bars with patented positioning design (7 sets)

- Reinforced imported main drive chain

- High-quality intermittent indexer

- High-quality timing belts and pulley transmission

- Imported pneumatic clutch brake for main drive

- Pneumatic dual-locking mechanism for die chase

- Pneumatic locking mechanism for adjustable die-cutting base plate

- One set of spare gripper bars

- Two sets of quick-lock die chases

Blanking Unit

- Powered upper blanking frame mechanism

- Pneumatic lifting for upper blanking frame

- Pneumatic quick-locking system for upper blanking frame

- Pull-out lower blanking tool support frame

- Fine-tuning device with digital display for blanking tool frame

- Non-stop collecting and counting system for uninterrupted product collection with quantity setting

- Automatic delivery system

Delivery Unit

- Bi-directional mechanical sheet aligner

- Mechanical sheet deceleration and brushing system for easy operation

- Compressed air sheet press device

- Pneumatic sheet sampling mechanism

- Manual auxiliary delivery system for independent operation at start-up

- 2 delivery pile trays

- Electrical System

- 10” true color touch screen

- Mitsubishi Q Series PLC

- High-quality low voltage control components

- High-quality sensors and limit switches

- Emergency stop circuit detection, safety doors, and redundant dual-circuit design

- Full machine electrical system complies with CE design standards and CE regulations

Others

- One set of foot pedals

- One toolbox

- One operation manual

- One maintenance manual

- One exploded diagram