Nội dung bài viết

ToggleMÁY ÉP NHŨ KIM 2 VÙNG LÀM VIỆC MK DUOPRESS 106VFF

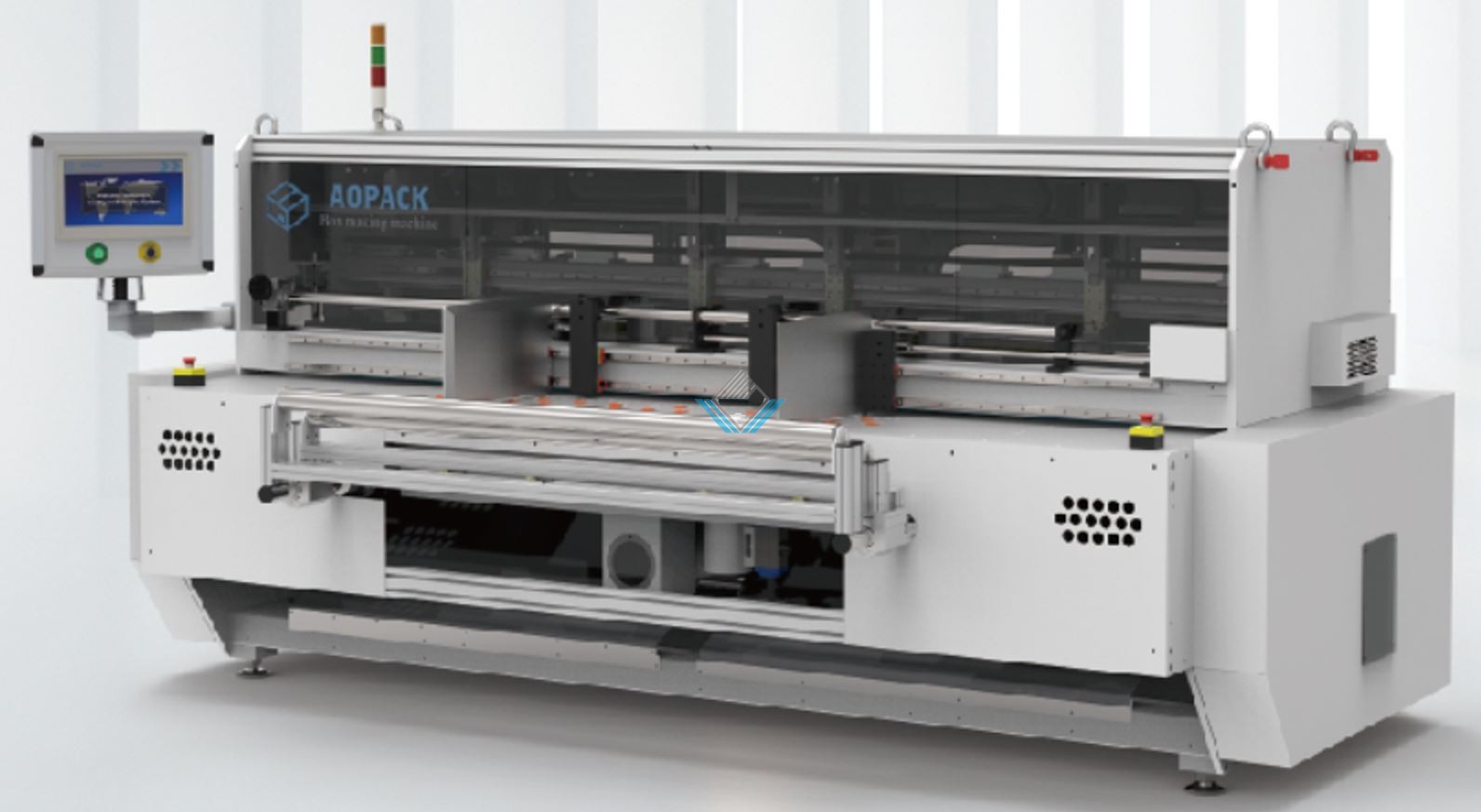

Hình ảnh máy ép nhũ kim 2 vùng làm việc MK Duopress 106VFF:

(The picture is only for reference, please make the object as the standar)

Giới thiệu về thương hiệu MK – Masterwork:

Thông số kỹ thuật máy ép nhũ kim 2 vùng làm việc MK Duopress 106VFF:

Technical parameters(Standard)

|

Maximum sheet size: |

: 1060 x 760mm |

| Minimum sheet size |

: 400mm×350mm |

|

Maximum die cutting size |

: 1060 x 745mm |

| Maximum stamping size |

: 1060 x 740mm |

|

Maximum embossing size |

: 1060 x 740mm |

| Gripper margin |

: 9~17mm |

|

Inner chase size |

:1120mmX770mm |

|

Convertible stock |

: Cardboard: 0.1-2mm (90-2000 g/m2) Corrugated: Max. 4.0mm(Flatness should be less than 20mm/m2) |

|

Max. operating pressure |

: 1st unit 600T : 2nd unit 600T |

|

Max. working speed |

: 5000 sheet per hour(foil stamping& die cutting) |

| Max. feeder pile height |

: 1,400mm(including pallet) |

|

Max. delivery pile height |

: 1,200mm(including pallet) |

| Max. diameter of foil roll |

: Machine direction /Longitudinal direction: 250mm Transversal direction: 200mm |

|

Main motor power |

: 18.5KW |

| Number of heating zone of Unit 1 and Unit 2 |

: 20 zones (Individual adjustable from 40-180 ℃) |

|

Width of aluminum foil |

: 20~1060mm |

| Electrochemical aluminum foil feeding system of Unit 1 and Unit 2 |

: 3 Longitudinal shafts + 2 transversal shaft |

|

Overall dimensions (L x W x H) |

: 8676mm (L) x 5565mm (W incl operation platform) x 2930mm (H) |

| Weight |

: Approx. 40T |

|

Air source requirements |

: Pressure 0.6~0.7Mpa, flow rate >1 m3/min |

| Accuracy of repeated registering |

: ≤±0.10mm |

|

Full load power |

: 95KW |

| Rated power |

: 55KW |

Standard Devices and Functions(Standard):

- Non-stop high-speed feeding unit

- Non-stop high-speed sheet feeding unit

- The stream type paper feeder has its max speed more than 108 pages per minutes.

- Sheet slow down when sheet arrives at front guide

- Adjustable wind suction duct.

- 3 feeder anti-collision devices

- Motorized lateral paper pile adjustment

- Push and pull side guide

- Electric side horizontal blower and paper proctor device

- Feeding chase uplifts by gas spring device

- Electromechanical double-sheet detector

- Imported sheet transferring belt

- Side guide and front guide paper photoelectric detection

- The single point electromagnetic positioning clutch, which ensures every paper can be reached to the front lay position at any starting time, that make adjustable time shortened.

- The master and assistant sheet feeding pile can alternate subject to no downtime, with the feeder working without stop.

- Powerful sheet suction feeder with four suction heads and four feeding heads for adjusting sheet suction angle according to sheet deformation.

- The suction and sliding valve are made from superhard alloy.

- Sheet feeding and die cutting can be separately controlled by means of different switches.

- Paper pressing belt and brush roller components (2 sets)

- Brush roller components (each 4 sets , soft and hard)

- Paper pressing wheel combinations (10 sets)

- Paper pressing ball assemblies (4 sets)

- Non-stop feeding pallets (2pcs)

- Paper inserting rod (1 set)

- Becker vacuum air pump

- Two Die cutting units

- Main machine pressure generation mechanism and power drive mechanism.

- Servo drive pressure regulating mechanism for unit 1 and unit 2

- Full set of worm gear and worm

- Ductile iron foundation, left and right wallboard as well as upper and lower platform, with resin sand technique.

- The die-cutting lower base plate is equipped with a 3+1.2mm steel plate.

- 2mm die cutting plate 2 pcs

- Cutting chase and honeycomb chase turnover device

- Lubricating oil cooling and lubricating system for the main transmission box

- Torque limit overload protection.

- Complete set of gripper bar with adjustable system, 11 pcs total. (11 groups).

- Strengthened drive chain

- Imported intermitted splitter.

- Imported synchronization belt and belt wheel drive

- Main drive pneumatic clutch brake device imported.

- Die cutting chase bidirectional pneumatic locking system

- Lower cutting-plate pneumatic locking system.

- Electric heating system, the temperature is independently controlled in 20 different zones, with the sensitive temperature difference within ± 5°C.

- Foil stamping control computer system

- 1 Spare gripper bar

- Die cutting chase 2 sets

- Honeycomb chase 4 sets

3、Machine direction foil control of Unit 1 and Unit 2

- 3 machine direction foil shafts driven by servo motor. Foil feeding from high position, Max. foil diameter φ250mm;.

- Motorized external brush roller for used foil collection.

- 6 sensors for machine direction foil breakage detection.

- Blower device for machine direction foil separating.

- Telescopic foil feeding frame

- Foil stamping control computer system

4、Cross direction foil control of Unit 1 and Unit 2

- 2 transversal shafts, foil diameter φ200mm;

- Blower device for cross direction foil separating

- 2 sensors for cross direction foil breakage detection.

- Horizontal waste foil rolling-up with constant tension.

5、Delivery unit

- Bidirectional mechanical paper aligning device

- Paper damping deceleration mechanical sheet delivery and paper pressing brush mechanism, convenient for operation.

- Blower bar from upper side and front side for smooth paper collection

- Manually aux-delivery device

- Pneumatic sheet sampling device

- Delivery pallets 2 pcs

- Chain drive device

- Gripper bar lubrication device

6、Electrical unit

- Electrical cabinet 2set

- Foil stamping control cabinet 2 sets

- Color HMI 10.4” 2pcs

- CE certification

7、Others

- Steel operation platform 1 set

- Sample checking table 1 set

- Tool box 1 set

- Operator manual 1 set