Nội dung bài viết

ToggleMÁY DÁN HỘP MK DIANA EASY PLUS 85 – Master Work

Hình ảnh máy dán hộp MK Diana Easy Plus 85 – Master Work:

Option tuỳ chọn:

Đầu cấp giấy:

Thu giấy tự động kiểu đơn giản:

Thu giấy đóng gói thông minh:

Video máy dán hộp MK Diana Easy Plus 85 – Master Work:

Giới thiệu về thương hiệu MK – Masterwork:

Thông số kỹ thuật máy dán hộp MK Diana Easy Plus 85 – Master Work:

Xem thêm:

CÁC LOẠI MÁY BẾ TỰ ĐỘNG HÃNG MK

CÁC LOẠI MÁY KIỂM PHẨM HÃNG MK

MÁY IN DỮ LIỆU BIẾN ĐỔI HÃNG MK

Technical specifications of equipment (Standard)

- Material

| paper(g/m2) | Corrugated board | |

| Blanks | 200 … 600 | N-, F-, E- fine corrugated board |

Table. 1

- Installation space

|

Diana Easy Plus 65 |

|

|

Length |

16.5 m |

| Width |

1.3 m |

Table. 2

|

Diana Easy Plus 85 |

|

|

Length |

16.5 m |

| Width |

1.5 m(2.4m) |

Table. 3

|

Diana Easy Plus 115 |

|

| Length |

16.5 m |

|

Width |

1.8 m(2.7m) |

Table. 4

- Air source

|

Basic machine |

Compressed air(bar) | Pressure (PSI) | Max. Air comsume(L/min) |

| Diana Easy Plus 65/85/115 | 6.0 | 87 |

85 |

Table. 5

|

Modular(optional) |

Compressed air(bar) | Pressure (PSI) | Max. Air comsume(L/min) |

| Rejection module | 6.0 | 87 |

20 |

Table. 6

|

Attachments (optional) |

Compressed air(bar) | Pressure (PSI) | Max. Air comsume(L/min) |

| Boxes stack stripping blowing | 6.0 | 87 |

128 |

|

Vacuum feeder, every suction belt ( max. 4 belts) |

6.0 | 87 | 178 |

| Gluing edge grinder | 6.0 | 87 |

684 |

|

Lower glue tank automatic glue pump |

6.0 | 87 | 3 |

| CD box | 6.0 | 87 |

50 |

|

Plastic nozzle, each nozzle(max. 3) |

6.0 | 87 | 44 |

| Code reader | 6.0 | 87 |

33 |

|

Gluing control device |

6.0 | 87 | 0 |

| Nozzle type Gluing | 6.0 | 87 |

10 |

Table. 7

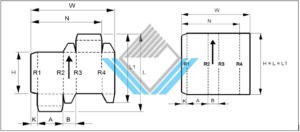

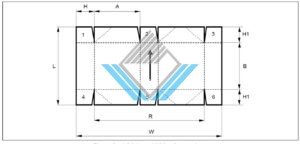

Figure. 2 standard box type

|

Diana Easy Plus65 |

K | A | B2) | A +B | W | L | N | ||||||||

| min. | max. | min.1) | min. | max. | min. | min.1) | min. | max. | min.1) | min. | max. |

min. |

max.3) | max. | |

|

mm |

5 | 40 | 10 | 25 | 262.5 | 10 | 20 | 35 | 322 | 45 | 75 | 650 | 55 | 600 | 540 |

| inch | 1/5 | 1 4/7 | 2/5 | 1 | 10 1/3 | 2/5 | 4/5 | 1 3/8 | 12 2/3 | 1 7/9 | 3 | 25 3/5 |

2 1/6 |

23 5/8 | 21 1/4 |

Table.8

|

Diana Easy Plus 85 |

K | A | B2) | A +B | W | L | N | ||||||||

| min. | max. | min.1) | min. | max. | min. | min.1) | min. | max. | min.1) | min. | max. |

min. |

max.3) | max. | |

|

mm |

5 | 40 | 10 | 25 | 362.5 | 10 | 20 | 35 | 422.5 | 45 | 75 | 850 | 55 | 600 | 728 |

| inch | 1/5 | 1 4/7 | 2/5 | 1 | 14 | 2/5 | 4/5 | 1 3/8 | 16 5/8 | 1 7/9 | 3 | 33 1/2 |

2 1/6 |

23 5/8 | 28 11/16 |

Table.9

|

Diana Easy Plus 115 |

K | A | B2) | A +B | W | L | N | ||||||||

| min. | max. | min.1) | min. | max. | min. | min.1) | min. | max. | min.1) | min. | max. | min. | max.3) | max. | |

| mm | 5 | 40 | 10 | 25 | 506.5 | 10 | 20 | 35 | 572.5 | 45 | 75 | 1150 |

55 |

600 | 1028 |

|

inch |

1/5 | 1 4/7 | 2/5 | 1 | 20 | 2/5 | 4/5 | 1 3/8 | 22 1/2 | 1 7/9 | 3 | 45 2/7 |

2 1/6 |

23 5/8 | 40 1/2 |

Table.10

|

1) with minature box attachment 2) if B>A, the value of A+2B shall be no more than: 638 mm (Diana Easy Plus 85) 956 mm(Diana Easy Plus 115) 3) If L >450mm, the prefolding line R3 can reach 90° maximum. |

||

|

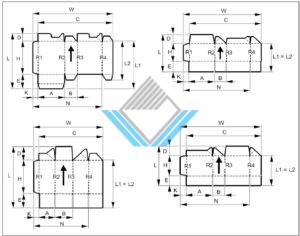

- Lockbottom box

Figure. 3 Lockbottom box

|

Diana Easy Plus 65 |

K | A | B | A +B | W | L1 | L* | N | D | H | ||||||

| min.* | max. | min.* | max. | min. | min.* | max. | min. | max. | min. | max. | max. | max. | min. | max. | min. | |

| mm | 6 | 40 | 40 | 230 | 30 | 70 | 306 | 146 | 650 | 55 | 600 | 800 |

530 |

30 | 200 | 50 |

|

inch |

1/4 | 1 4/7 | 1 4/7 | 9 | 1 1/6 | 2 3/4 | 12 | 5 3/4 | 25 3/5 | 2 1/6 | 23 5/8 | 31 1/2 |

20 6/7 |

1 1/6 | 7 7/8 | 2 |

|

Diana Easy Plus 85 |

K | A | B | A +B | W | L1 | L* | N | D | H | ||||||

| min.* | max. | min.* | max. | min. | min.* | max. | min. | max. | min. | max. | max. | max. | min. | max. | min. | |

| mm | 6 | 40 | 40 | 330 | 30 | 70 | 406 | 146 | 850 | 55 | 600 | 800 |

720 |

30 | 200 | 50 |

| inch | 1/4 | 1 4/7 | 1 4/7 | 13 | 1 1/6 | 2 3/4 | 16 | 5 3/4 | 31 1/2 | 2 1/6 | 23 5/8 | 31 1/2 | 28 1/3 | 1 1/6 | 7 7/8 | 2 |

|

Diana Easy Plus 115 |

K | A | B | A +B | W | L1 | L* | N | D | H | ||||||

| min.* | max. | min.* | max. | min. | min.* | max. | min. | max. | min. | max. | max. | max. | min. | max. | min. | |

| mm | 6 | 40 | 40 | 480 | 30 | 70 | 556 | 146 | 1150 | 55 | 600 | 800 |

1028 |

30 | 200 | 50 |

|

inch |

1/4 | 1 4/7 | 1 4/7 | 18 8/9 | 1 1/6 | 2 3/4 | 21 8/9 | 5 3/4 | 45 2/7 | 2 1/6 | 23 5/8 | 31 1/2 |

40 1/2 |

1 1/6 | 7 7/8 | 2 |

Table. 13

|

* Pay attention of the following limit and attachments of lockbottom box. |

||

|

Special requirement K Gluing edge is between 10mm and 20mm, 5mm glue disk is recommended. Gluing edge is less than 10mm, 3mm glue disk is recommended. W • <190mm, small lockbottom box attachment is recommended. |

||

|

Requirement to paper fiber direction: • H : C> 1 : 4: perpendicular to running direction • H : C< 1 : 4: be parellel to running direction |

||

|

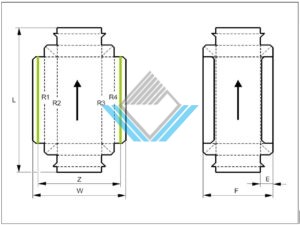

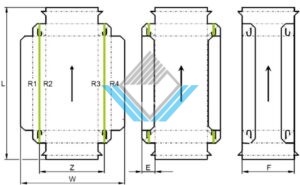

Unilateral folded double wall folding box

Figure. 4 Unilateral folded double wall folding box

|

Diana Easy Plus65 |

L | F | W | Z | E* | ||

| min. | max. | min. | max. | max. | min. | min. | |

| mm | 120 | 600 | 90 | 406 | 650 | 105 |

15 |

|

inch |

4 5/7 | 23 5/8 | 3 1/2 | 16 | 25 3/5 | 4 1/7 |

3/5 |

Table. 14

|

Diana Easy Plus85 |

L | F | W | Z | E* | ||

| min. | max. | min. | max. | max. | min. | min. | |

| mm | 120 | 600 | 90 | 556 | 850 | 105 |

15 |

|

inch |

4 5/7 | 23 5/8 | 3 1/2 | 21 8/9 | 33 1/2 | 4 1/7 |

3/5 |

Table. 15

|

Diana Easy Plus 115 |

L | F | W | Z | E* | ||

| min. | max. | min. | max. | max. | min. |

min. |

|

|

mm |

120 | 600 | 90 | 600 | 1150 | 105 | 15 |

| inch | 4 5/7 | 23 5/8 | 3 1/2 | 23 5/8 | 45 2/7 | 4 1/7 |

3/5 |

Table.16

|

* E max. = W:6 |

||

|

Bilateral folded and glued double wall folding box

Figure. 5 1.2.4 Bilateral folded and glued double wall folding box

|

Diana Easy Plus65 |

L | Z | W | E* | F | ||

| min. | max. | min. | max. | min. | min. | max. | |

| mm | 120 | 600 | 120 | 650 | 30 | 90 |

406 |

|

inch |

4 5/7 | 23 5/8 | 4 5/7 | 25 3/5 | 1 1/6 | 3 1/2 |

16 |

Table . 17

|

Diana Easy Plus85 |

L | Z | W | E* | F | ||

| min. | max. | min. | max. | min. | min. | max. | |

| mm | 120 | 600 | 120 | 850 | 30 | 90 |

600 |

|

inch |

4 5/7 | 23 5/8 | 4 5/7 | 33 1/2 | 1 1/6 | 3 1/2 |

21 8/9 |

Table . 18

|

Diana Easy Plus115 |

L | Z | W | E* | F | ||

| min. | max. | min. | max. | min. | min. | max. | |

| mm | 120 | 600 | 120 | 1150 | 30 | 90 |

600 |

|

inch |

4 5/7 | 23 5/8 | 4 5/7 | 45 2/7 | 1 1/6 | 3 1/2 |

23 5/8 |

Table.19

|

* E max. = W:6 |

||

|

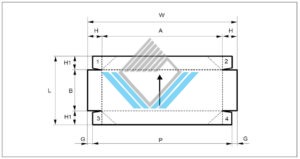

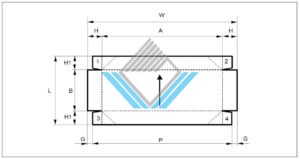

Inward folding 4 corner box without lid

Figure. 6 1.2.5 4 corner box with/without lid

|

Diana Easy Plus65 |

H /H1 | A | W | B | L | |||||

| min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | |

| mm | 20 | 140 | 80 | 406 | 120 | 650 | 70 | 400 | 110 |

680 |

|

inch |

4/5 | 5 1/2 | 3 1/7 | 16 | 4 5/7 | 25 3/5 | 2 3/4 | 15 3/4 | 4 1/3 |

26 7/9 |

Table. 20

|

Diana Easy Plus85 |

H /H1 | A | W | B | L | |||||

| min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | |

| mm | 20 | 140 | 80 | 600 | 120 | 850 | 70 | 400 | 110 |

680 |

|

inch |

4/5 | 5 1/2 | 3 1/7 | 23 5/8 | 4 5/7 | 33 1/2 | 2 3/4 | 15 3/4 | 4 1/3 |

26 7/9 |

Table.21

|

Diana Easy Plus115 |

H /H1 | A | W | B | L | |||||

| min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | |

| mm | 20 | 140 | 80 | 600 | 120 | 880 | 70 | 400 | 110 |

680 |

|

inch |

4/5 | 5 1/2 | 3 1/7 | 23 5/8 | 4 5/7 | 34 2/3 | 2 3/4 | 15 3/4 | 4 1/3 |

26 7/9 |

Table.22

|

* H/H1 max. 100 (can be 140 only when with two paws backfold hook installed, optional) |

||

|

Outward folding 4 corner box without lid

Firure. 7 Outward folding 4 corner box without lid

|

Diana Easy Plus65 |

G* | H /H1 | A | W | B | L | P | |||||

| min. | min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. | |

| mm | 20 | 30 | 160 | 80 | 406 | 140 | 650 | 70 | 400 |

130 |

600 |

610 |

|

inch |

4/5 | 1 1/6 | 6 2/7 | 3 1/7 | 16 | 5 1/2 | 25 3/5 | 2 3/4 | 15 3/4 | 5 1/8 | 23 5/8 |

24 |

Table 23

|

Diana Easy Plus85 |

G* | H /H1 | A | W | B | L | P | |||||

| min. | min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. | |

| mm | 20 | 30 | 160 | 80 | 600 | 140 | 850 | 70 | 400 | 130 | 600 |

715 |

|

inch |

4/5 | 1 1/6 | 6 2/7 | 3 1/7 | 23 5/8 | 5 1/2 | 33 1/2 | 2 3/4 | 15 3/4 | 5 1/8 | 23 5/8 |

28 1/7 |

Table.24

|

Diana Easy Plus115 |

G* | H /H1 | A | W | B | L | P | |||||

| min. | min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. | |

| mm | 20 | 30 | 160 | 80 | 600 | 140 | 920 | 70 | 400 | 130 | 600 |

880 |

|

inch |

4/5 | 1 1/6 | 6 2/7 | 3 1/7 | 23 5/8 | 5 1/2 | 36 2/9 | 2 3/4 | 15 3/4 | 5 1/8 | 23 5/8 |

34 2/3 |

Table.25

|

* H/H1 max. 100 (can be 160 only when with two paws backfold hook installed, optional) |

||

|

*建议: G = 0.3 x H |

||

|

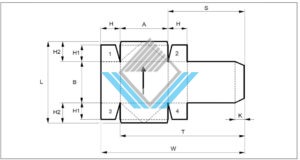

Inward folding 4 corner box with lid

Table. 8 Inward folding 4 corner box with lid

|

Diana Easy Plus65 |

K | H / H1 / H2 | A | W | B | L | T | S | ||||||

| min. | max. | min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. | max. | |

| mm | 10 | 88 | 30 | 100 | 80 | 249 | 230 | 640 | 70 | 400 | 130 | 576 |

528 |

360 |

|

inch |

2/5 | 3 1/2 | 1 1/6 | 4 | 3 1/7 | 9 4/5 | 9 | 25 1/5 | 2 3/4 | 15 3/4 | 5 1/8 | 22 2/3 |

20 4/5 |

14 1/6 |

Table. 26

|

Diana Easy Plus85 |

K | H / H1 / H2 | A | W | B | L | T | S | ||||||

| min. | max. | min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. |

max. |

max. | |

|

mm |

10 | 113 | 30 | 130 | 80 | 349 | 230 | 810 | 70 | 400 | 130 | 660 | 678 | 448 |

| inch | 2/5 | 4 4/9 | 1 1/6 | 5 1/8 | 3 1/7 | 13 3/4 | 9 | 31 7/8 | 2 3/4 | 15 3/4 | 5 1/8 | 26 |

26 2/3 |

17 2/3 |

Table.27

|

Diana Easy Plus 115(1) |

K | H / H1 / H2 | A | W | B | L | T | S | ||||||

| min. | max. | min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. |

max. |

max. | |

|

mm |

10 | 113 | 30 | 130 | 80 | 500 | 230 | 1110 | 70 | 400 | 130 | 660 | 1028 | 610 |

| inch | 2/5 | 4 4/9 | 1 1/6 | 5 1/8 | 3 1/7 | 19 2/3 | 9 | 43 11/16 | 2 3/4 | 15 3/4 | 5 1/8 | 26 |

40 1/2 |

24 |

Table.28

|

* H/H1 max. 100 (can be 140 only when with two backfold hooks installed, optional) (1) only effective if the compressiong section has the function of side to side regulationg, if not, the technical parameters of Diana Easy Plus 85 shall be applied. |

||

|

Inward folding 6 corner box

Figure. 9 1.2.8 Inward folding 6 corner box

|

Diana Easy Plus65 |

H /H1 | A | W | B | L | R | H + A | |||||

| min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. |

max. |

|

|

mm |

30 | 92 | 80 | 215 | 250 | 650 | 70 | 400 | 130 | 584 | 461.5 | 264 |

| inch | 1 1/6 | 3 5/8 | 3 1/7 | 8 1/2 | 9 5/6 | 25 3/5 | 2 3/4 | 15 3/4 | 5 1/8 | 23 | 18 1/6 |

10 2/5 |

Table. 29

|

Diana Easy Plus85 |

H /H1 | A | W | B | L | R | H + A | |||||

| min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. |

max. |

|

|

mm |

30 | 115 | 80 | 305 | 250 | 850 | 70 | 400 | 130 | 630 | 636.5 | 339 |

| inch | 1 1/6 | 4 1/2 | 3 1/7 | 12 | 9 5/6 | 33 1/2 | 2 3/4 | 15 3/4 | 5 1/8 | 24 4/5 | 25 |

13 1/3 |

Table. 30

|

Diana Easy Plus 115(1) |

H /H1 | A | W | B | L | R | H + A | |||||

| min. | max.* | min. | max. | min. | max. | min. | max. | min. | max. | max. |

max. |

|

|

mm |

30 | 115 | 80 | 475 | 250 | 1150 | 70 | 400 | 130 | 630 | 986.5 | 514 |

| inch | 1 1/6 | 4 1/2 | 3 1/7 | 18 5/7 | 9 5/6 | 45 2/7 | 2 3/4 | 15 3/4 | 5 1/8 | 24 4/5 | 38 5/6 |

20 1/4 |

Table.31

|

* H/H1 max. 100 (can be 115 only when with two paws backfold hook installed, optional) (1) only effective if the compressiong section has the function of side to side regulationg, if not, the technical parameters of Diana Easy Plus 85 shall be applied. |

||

|

||

|

Options:

- Gluing system with 2 guns and 2 control

- Z box attachments

Model: Diana Easy Plus 85 Equipment Name: High-Speed Automatic Box Gluing Machine Standard Configuration and Functions:

1 Paper Correction Section

1.1 The paper correction section has a length of approximately 1950mm and includes paper correction functionality.

1.2 It features paper knives, pneumatic lifting mechanisms for aligning paperboards.

1.3 Two sets of main paper knives, adjustable horizontally and vertically.

1.4 Six groups of 30mm friction paper belts for feeding paper, including two vacuum suction paper belts.

1.5 Includes 2 sets of 35mm wide lower pressure belt devices, 2 sets of upper pressure wheel devices, and left and right correction side rules.

1.6 Equipped with a blow-drying device for the paper belts.

1.7 Vibrating motor for paper feeding.

1.8 Paper separation blow-drying device.

1.9 Monitor at the feeder section to monitor paper transport.

1.10 Left and right glue folding pre-folding units.

1.11 Paper stack storage table.

1.12 Extended side alignment units for paperboards on the left and right sides.

2 Folding Section

2.1 The folding section has a length of approximately 3000mm.

2.2 Includes R1 and R3 line folding components (24mm wide lower pressure belts on the left and right sides, 2 sets of 24mm wide upper pressure belts on the left side, 1 set on the right side, and lifting supports).

2.3 R1 line folding component (glue folding pre-folding unit) with reserved space for barcode detection head installation.

2.4 R3 folding unit equipped with 24mm folding belts and includes a folding frame.

2.5 Folding expansion attachments on the left and right sides.

2.6 Middle paper support board.

2.7 Upper and lower middle conveyor belts.

3 Bottom Locking Section

3.1 The bottom locking section has a length of approximately 1730mm.

3.2 Includes 3 sets of 24mm wide lower pressure belts and 5 sets of upper pressure belt spring seats.

3.3 Equipped with accessories for locking boxes with a length-to-width ratio of 1:15, including hooks and bottom lock guards.

3.4 Bottom support board.

4 Folding Section

4.1 The folding section has a length of approximately 3000mm.

4.2 24mm wide lower pressure belts on the left and right sides; 24mm wide upper pressure belts on the left and right sides, adjustable in length.

4.3 24mm wide folding belts on the left and right sides.

4.4 Adjustable pressure end roller units for folding at the end of the unit on the left and right sides.

4.5 Mechanical variable speed devices for folding belts on the left and right sides.

4.6 Equipped with a detachable and washable glue bucket with a 5mm glue pan on the operating side.

4.7 Upper and lower middle conveyor belts, with the upper part being flippable and the lower part being detachable.

5 Conveyor Section

5.1 The conveyor section has a length of approximately 1400mm.

5.2 One upper pressure belt each on the left and right sides, manually adjustable front and back.

5.3 Two lower pressure belts each on the left and right sides, electrically adjustable.

5.4 End roller height adjustment device for upper and lower pressure belts.

5.5 Pneumatic counting device installable on the left and right sides.

5.6 15-inch human-machine interactive touchscreen.

5.7 Ejection module, including ejection channel.

5.8 Misfeed detection switch.

6 Pressure Section

6.1 The pressure section has a total length of 5000mm, with an effective pressing length of 3600mm and a belt width of 600mm.

6.2 One upper pressure belt, one lower pressure belt, and equipped with a deviation correction device.

6.3 Pneumatic pressure-adjustable upper and lower support rollers.

6.4 Automatic stop misaligned box monitoring device.

6.5 Two sets of automatic paper belt receiving devices.

6.6 Equipped with auxiliary pressure belts.

7 Electrical and Transmission System

7.1 Human-machine dialogue touchscreen operation mode.

7.2 Wireless remote control for controlling the entire machine’s actions.

8 Gluing System

8.1 Supports a maximum speed of 300m/min for the box gluing machine, with accurate gluing positions.

8.2 Stable switching between dot and line modes.

8.3 Four control units, two guns, and two photocells (expandable up to four guns and four photocells).

9 Auxiliary Equipment

9.1 Manuset (mechanical encoder).

9.2 Toolbox.